Professional mountain biker, one of the best German marathon riders and XC rider - Max, you have proven many times that you can be faster than anyone else. Now another own product. How come?

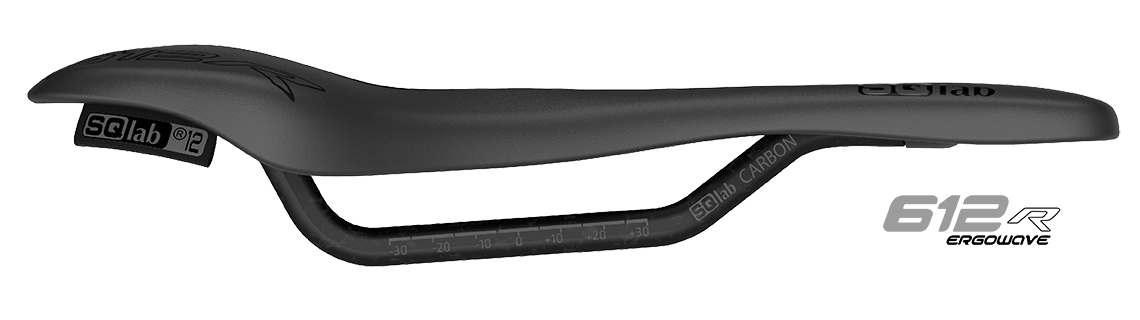

I studied sports science at the TU Munich, majoring in biomechanics. As always at the end of a degree, a thesis is part of it - as it is for me. So I was looking for topics that interested me on the one hand and that would be useful on the other. Since I was sponsored by SQlab at that time and at the same time employed as a working student, I got into conversation with boss Toby Hild. I suggested him to do my master thesis about a more detailed insight into the saddle pressure distribution on a mountain bike as well as a road bike, in a very sporty riding position. Since I myself have mainly raced on the 612 Ergowave saddle model, I wanted to examine exactly this in my study. This idea then brought my final topic: "Load-indexed changes in saddle pressure in cycling using a dynamic pressure measurement analysis of the SQlab 612 Ergowave saddle".

During the preliminary examinations and the first results, boss Toby and I sat together again for a meeting and I finally asked him "how serious" should I take the whole thing? I had neither a job nor a no concrete idea what should come after my studies.

So this master thesis meeting turned into a job interview, with the following statement from Toby: "Do the master thesis as good as you can and if the results are decisive enough to improve the 612 Ergowave even more, then do that!

The permanent position with the prospect of an own product was a great sign of confidence from Toby to me, who motivated me a lot for my following work.

SQlab is known for ergonomic saddles, the new 612 R is a redesign. Why?

Yes, it is a redesign of the 612 Ergowave saddle. The results of my master thesis showed that the 612 Ergowave saddle is not the right saddle for all conditions. This means that the 612 Ergowave saddle works perfectly for extensive and also sporty cycling and remains our recommendation for this area of use.

However, with higher loads as well as a strong saddle elevation in a very sporty riding position, I have noticed changes in the pelvic position in my study.

This leads to a different distribution of pressure on the saddle. In short, riders in the very sporty, competition-oriented area need a different relief. The shape of the 612 R saddle has been redesigned to meet these needs and offers a better pressure distribution for this area of use through a stronger waist and a narrower and shorter saddle nose. The saddle width system is still in the foreground with this saddle and so the 612 R saddle is available in 3 different widths and can be used by men and women alike.

Who is the 612 ERGOWAVE® for and who is the 612 R for?

The 612 Ergowave is for road or MTB race riders who tend to ride long distances and want to sit more upright on the bike (max. +2 seat position, saddle to handlebars at the same height).

The 612 R, on the other hand, is for road and MTB XC riders who like to ride fast, maybe even race. They have a sporty, stretched out seating position, which means that the saddle is very high (max. +1 seat position, handlebars lower than saddle). The new 612 R Ergowave saddle continues to provide relief for the perineal area at high intensities, as well as sufficient legroom for muscular thighs. At the same time it provides sufficient comfort over long distances. Provided that you measure yourself with the SQlab sit bone measurement and calculate your saddle size correctly!

Ergonomics in racing, but also in hobby sports - Why is it so important and what makes the difference?

Ergonomics is the key to success. Every engine only runs as fast as it is adjusted. If the gears don't run optimally into each other, it simply doesn't run smoothly enough to keep up with the best. Formula 1 gives a pretty good example. There, it is no longer the driver alone who wins the race, but to a large extent the engineers who get the last percent out of the car. The same can be said about the connection points from rider to bike. If the saddle doesn't fit perfectly, there are problems at that point and these force us to adopt a gentle posture from which 100% power delivery is no longer possible. The same applies to the hands and feet. This is the ergonomic idea that drives me.

Your master's thesis has now been awarded the "Dr. Gertrude Krombholz Prize 2019" by the TU Munich. Obviously it is so good that you will publish it and the 612R has already received several awards from the industry. Let's face it, that's quite a praise, isn't it?

Absolutely. At the moment I can't complain. It's going great. I wouldn't have thought so myself, because the transition from university to work is usually very difficult. Besides, Toby's footsteps as a "mega" successful and experienced saddle manufacturer were really big. I think this thought, that I have to give everything to be able to go along with it somehow, has got everything out of me that I could. On the one hand in the master thesis, but also in the product itself. As a racer, I'm used to pushing my limits, so I really enjoyed the whole thing.

A product is always as good as the whole team. How does product development actually work in practice and how does it work at SQlab?

Yes, that is absolutely true. Without the team around me, it would never have succeeded. I really had no experience how to approach the topic. But Mitch (Head of Product Management), Toby and Stephan (CAD) were very supportive and helped me at all times.

First you need the idea, then you play out whether it's even worth developing something new in the field. Then you think about concrete specifications that are to be implemented by the designers. For us, the idea of ergonomics or function is the first priority. As soon as the design is finished, the small details that make our products at SQlab special come into play. It can happen that we spend several hours together in front of the computer on the CAD model, lifting, lowering, turning etc. the tenths of a millimetre to the right or left of the products. Once the product has passed through the PC from our side, we have stable 3D prints made in order to test the product in reality and in the laboratory with the help of pressure gauges. This usually involves further improvement loops and also 3D printing loops. Only when we are completely sure, we send our designs to our producer. The producer usually has some changes, so there are a few more loops until it fits all parties involved.

Afterwards, the choice of material, hardness and design is done in close cooperation with the marketing department. Only then is production started and even that usually takes another 4-6 months. So all in all, no process that is completed within a few weeks.

The "Performance Line" does not "only" include a product, but also new grips and Innerbarends®. What is the goal?

After reworking the 612 Ergowave, I took a look at the grips and the Innerbarends and made the 711 into the 711R, and the 411 R Innerbarends out of the existing ones. Both were reduced in weight without any loss of comfort and ergonomics. For the 711R grip we used a new, very light material that works without a clamp, can take an ergonomic shape and at the same time offers enough cushioning, despite a very low weight of 59g/pair. The Innerbarends 411R are the absolute minimalist and most effective we have in our SQlab product range. Weighing only 39g together, they are made of one piece of carbon and offer a 5% performance improvement by changing the hand position. That should be enough arguments, right?

Also part of our new Performance Line is the SQ-Short ONE12 with a 4mm thin padding, which offers more comfort than any other shorts or shorts pad on the market due to little but very compressed material.

I am sure it will not stop there and the Performance Line will grow in the coming months.

Performance is for me...

a basic setting.

.contact)